It is typical to see flux residues when performing through hole mounting of component pins. The question is whether the residues are harmful to the electronics functionality. If the flux residue is exposed to high temperature and humidity it can change morphology and open up its structure for release of active acids. This is the white residues that can be seen for failure returns and PCBA´s exposed to varying temperatures and high humidity.

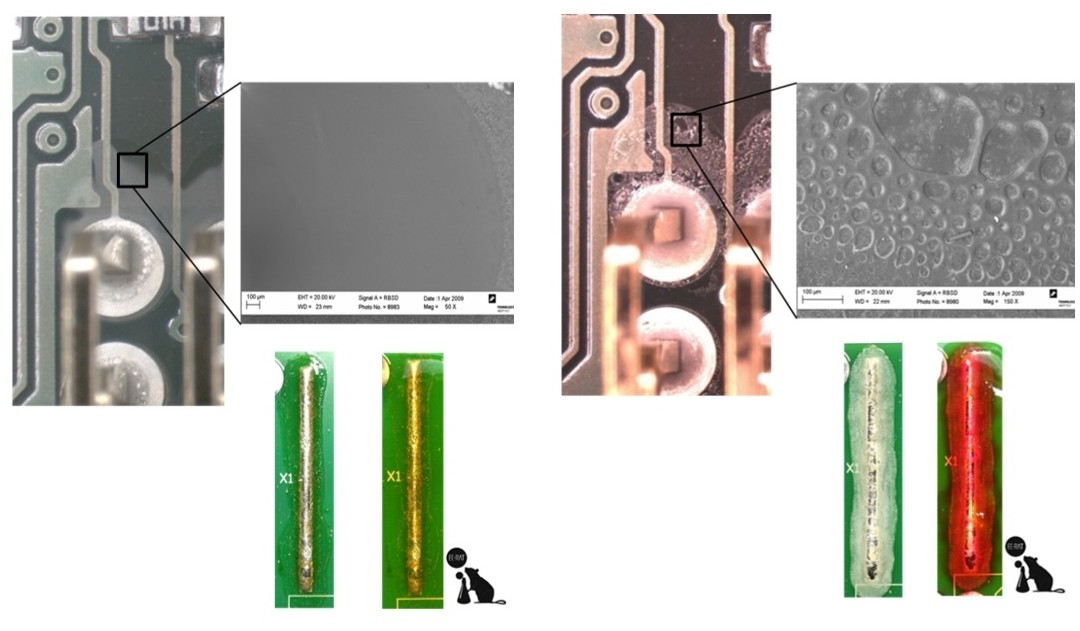

When testing solder paste flux residues before and after humidity exposure with Residues RAT there is a clear red coloration for the reflow solder paste that have been exposed to high humidity. This means that active acids have been released from the reflow solder paste and can act as a corrosion accelerator causing leakage current and a risk for electrochemical migration.

Reference PCB with solder paste flux residue PCB after 48 hours at 60°C/99%RH