Contamination with active organic acid, as can be found in unreacted flux residues has been reported to increase silver sulphide formation rate and amount. Environmental conditions such as humidity, temperature, contamination and gases affect the reliability and lifetime of electronic products. Sulphur polluted environments include regions near volcanic activity, pig farms, rubber manufacturing plants, oil refineries, coal-generation power plants, paper and pulp industry. Failure analysis of electronic products exposed to an environment containing sulphur gas typically show uniform corrosion and/or migration of silver and copper. Conformal coating is not always the adequate countermeasure against sulphur induced corrosion since gases can permeate through conformal coating and react with metals at the printed circuit board especially silver, copper and alloys hereof. Residues Rat was used as a product to detect flux residues prior to exposure of samples to sulfur gas. The combination of high humidity and flux residues was reported to drastically increase corrosion of silver in sulphur gaseous environment of a ceramic hybrid thick film substrate with conducting lines of silver and various contact pads, resistors, capacitors and integrated circuits.

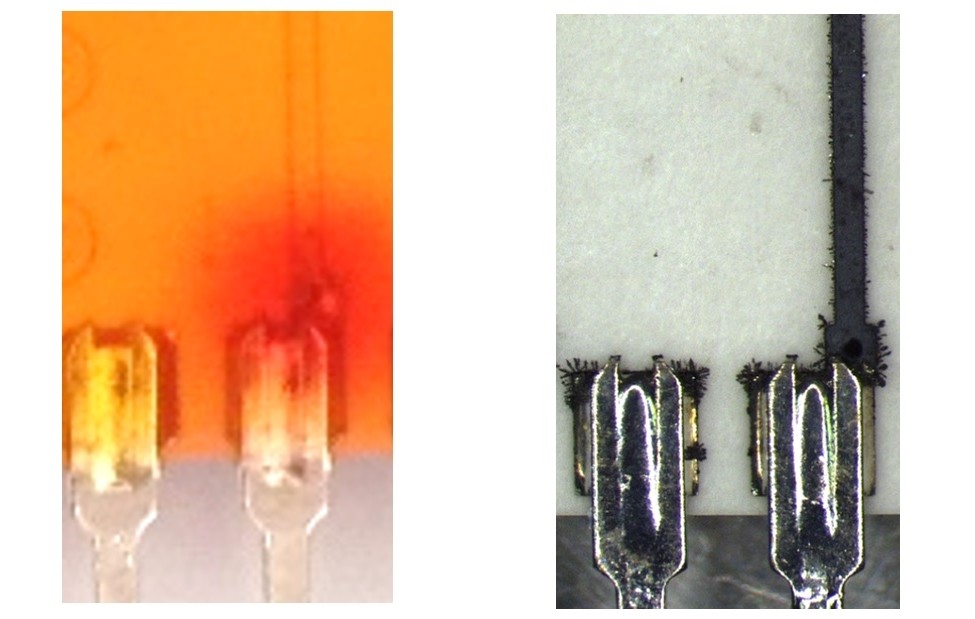

Residues RAT testing prior to sulfur test/After sulfur test

Source: [Sulphur induced corrosion of electronics, M. S. Jellesen, V. Verdingovas, S.Davidsdottir, R.Ambat, Proceedings of EuroCorr 2015]